Rimera Group’s Almetievsk plant (part of ChelPipe Group) has designed and begun production of 81 mm and 117 mm new AC electric motor models.

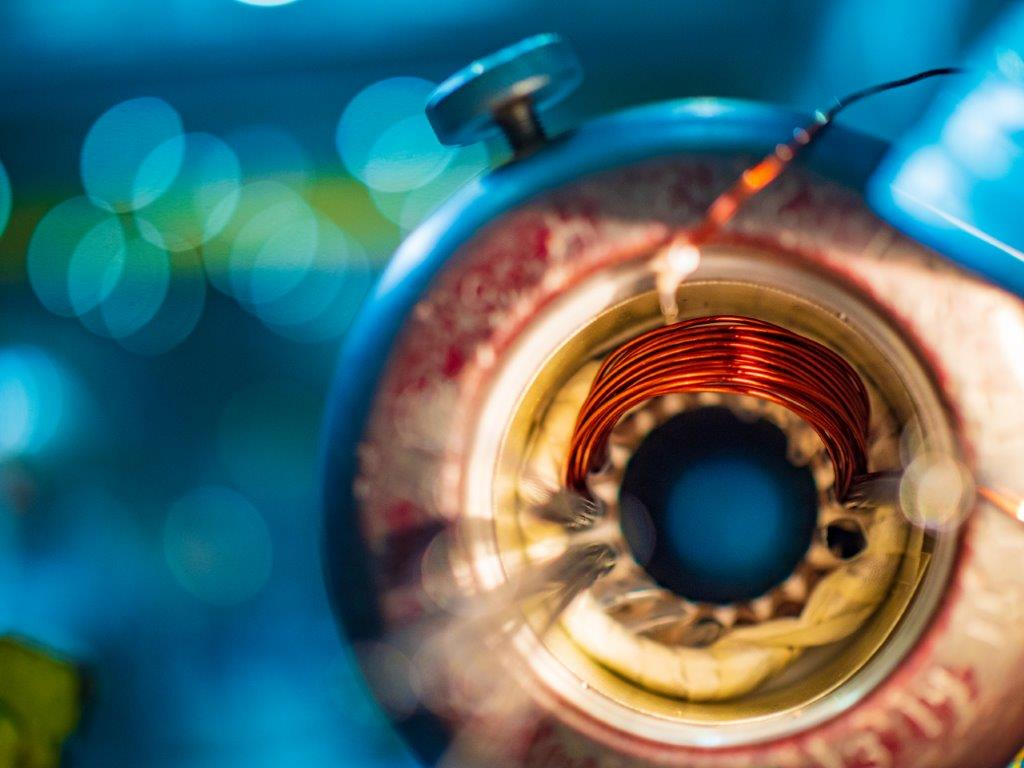

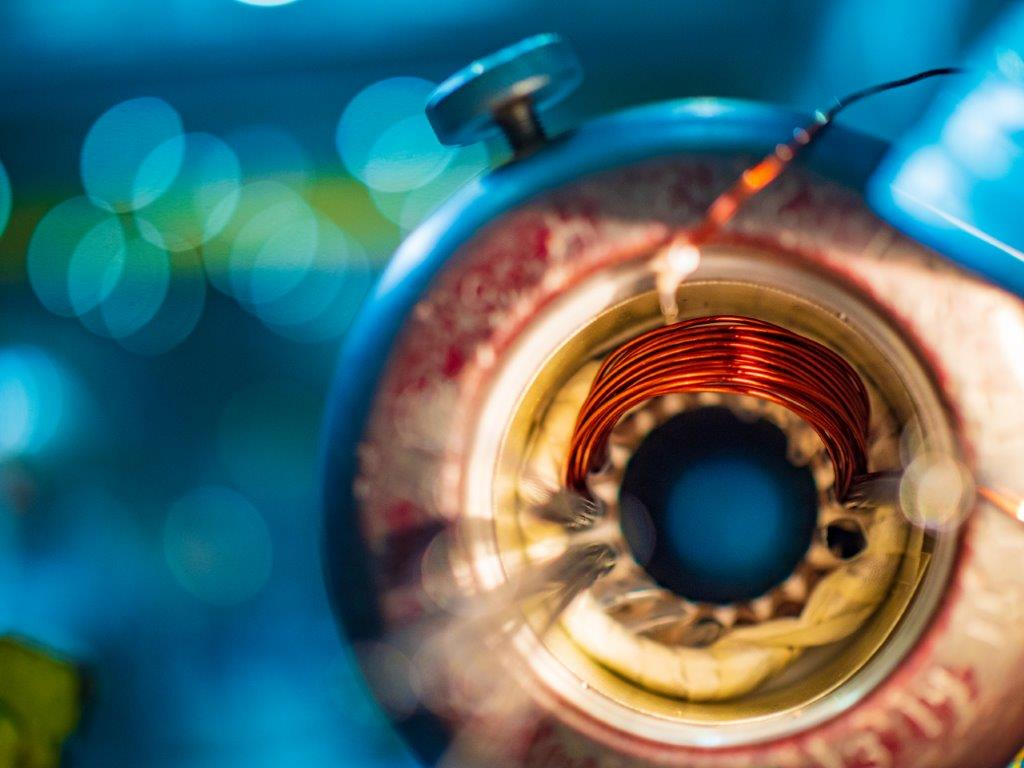

The Alnas plant designed new-generation submersible AC motors with over 90% efficiency, meeting the specifications of top Russian oil producers. As opposed to conventional asynchronous motors, AC motor rotor packs have permanent magnets and a special circuit, which feeds the voltage to stator windings via a control station. As a result, the motors use less energy, support smooth speed control and have better starting characteristics.

Eighty-one millimeter AC motors are used in small size 2A and 3 ESP systems, which are designed for oil production in difficult wells, workover wells and sidetracks. The AC motor is started and controlled off a ground-based control station, which enables optimizing fluid production to suit the flow rate by precise motor speed adjustment.

"The oil production equipment of Rimera Group meets current client needs and market trends characterized by an increasing demand for energy-saving equipment. The new AC electric motors made by Alnas use less energy and have better thermal output, which greatly extends the service life of the ESP. Due to high motor efficiency, operating costs of oil production can be reduced by 10-35%," said Alnas Operations Director Ildar Khairullin.

In 2021, Alnas plans to begin batch production of high-efficiency ESP stages of size 2A, 5, 5A and 6, and energy rating E2 and E3.